|

Product

|

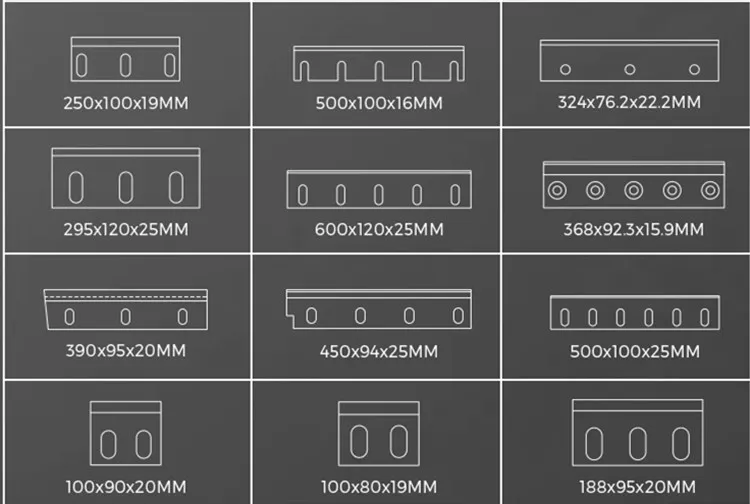

Sharp Cutting Edge Standard Steel Polar Paper Cutting Machine Blade |

| Suitable for equipments as |

POLAR, PERFECTA, ITOH, WOHLENBERG and many more |

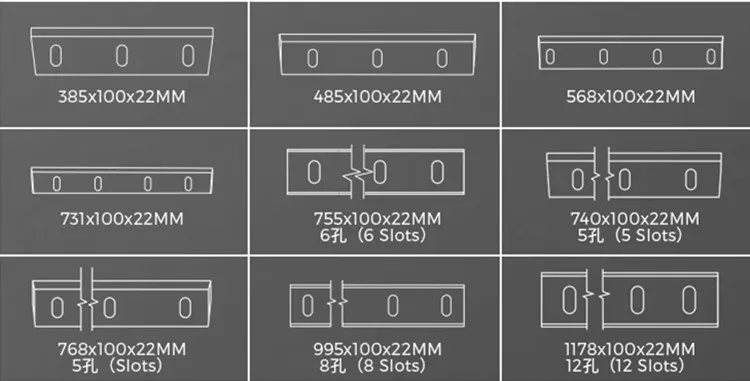

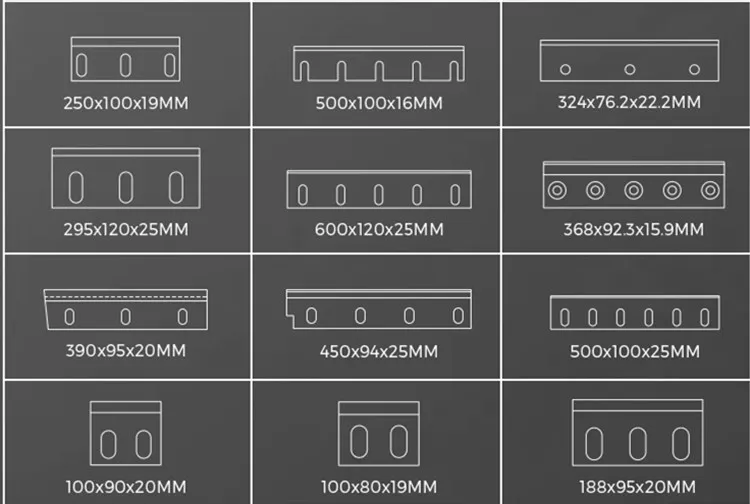

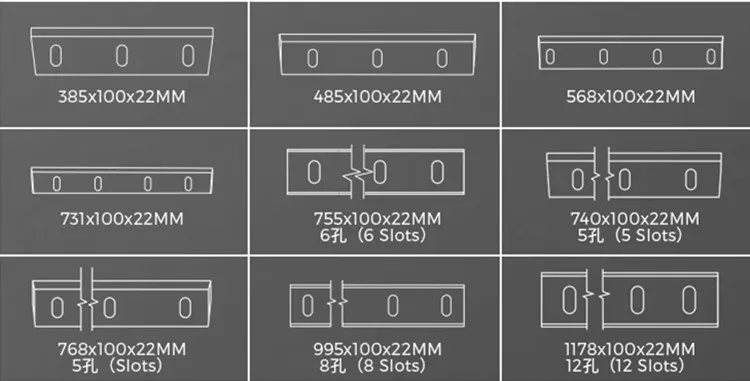

| Size |

As per machine model, or customized |

|

|

Inlaid Standard Steel, Inlaid HSS, Inlaid Carbide |

| Hardness |

61 ~ 63 HRC, or as request |

| OEM service |

Available |

| Certification |

TÜV, SGS |

| Main Market |

Europe, North America, Oceania etc |

| Packaging |

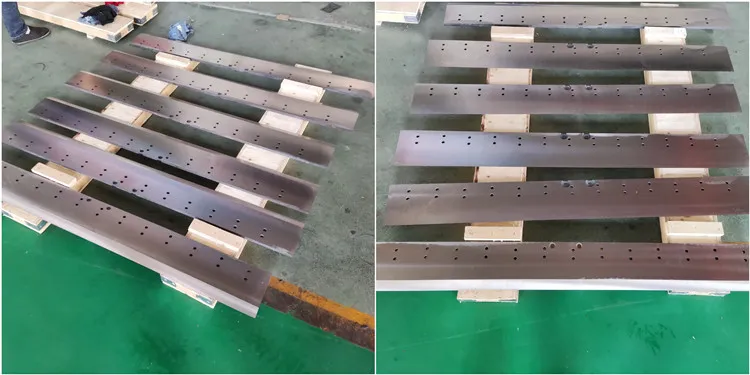

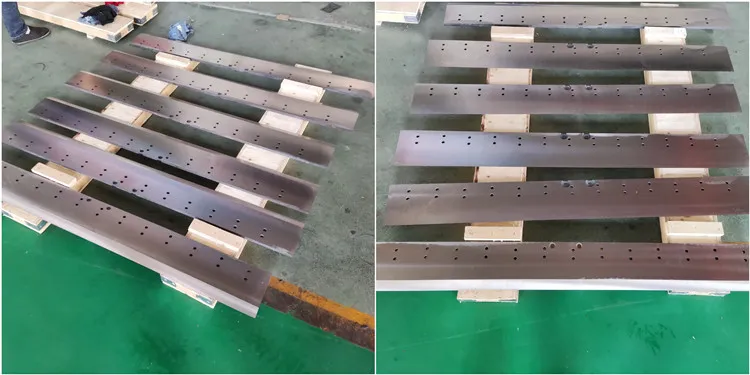

Wooden box or customized packing. |

Detailed Photos

Company Profile

Senda has been in the industrial blades and knives since 1998, we specialized in providing the replacement of blades for all the equipment from our large stock and professional services. Senda offer blades and knives for many industrials mainly for metal, paper and wood fields, providing our best services for the customers all over the world.

Senda located at Wuxi Xishan Industrial Zone, starting from 1998, we focus on the quality of products and provide better service. Now we have over 100 workers, CNC lathes, High precision internal and external circular grinding machines, heat-treatment furnaces grinding machines and inspection machines.

Senda history:

1998 the founder Alex Lee established the Senda factory, there’s only 6 employees at the beginning.

2000 Senda built the own heat-treatment workshop for the blades.

2003~2005 we build the cooperation with the largest steel factory in China, Bao Steel, on the research and development of new material, and providing the blades for Bao Steel.

2006~2007 Senda invite German professionals to our factory to guide the heat-treatment process and technology, and perfect our quality management system and new testing equipment.

2008 Senda knives for paper and metal industrials were ready for export.

2011~2013 Senda developed the SLD material specially used for shearing high strength steel. And we also start to make the tungsten carbide knives.

Till now, we are still focus on research and development of new material and products, seeking more foreign markets shares to build a popular brand.

Our Services

1. OEM and customized service.

2. Full machining, primer coating, surface treatment.

3. Complete material testing process.

4. Quality control

FAQ

Q1: Are you trading company or manufacturer ?

A1: Our factory is a professional manufacturer of machinery blades for more than 20years.Our blades are mainly used in: packaging, paper, rubber, optoelectronics, electronics, light industry, printing, metallurgy, and other machines.

Q2: what is your blade hardness?

A2: Different material has different hardness, from 48HRC to 68HRC, we both have. You can advice the function of your blade, we can provide suitbale suggestion for you.

Q3: What is your advantage if I choose you?

A3: 1. End manufacturer with competitive factory price.

2. Different raw materials for you to choose, we can give a professional suggestion to you.

3. Various blades for you to choose, OEM&ODM is supported.

4. High wear resistance and waterproof. 5. Short delivery time & safe packaging.

Q4: How long is your delivery time?

A4: Generally it is 3 days if the goods are in stock. or it is 15-45 days if the goods are not in stock, it is according to quantity.

Q5: Do you provide samples ? is it free or extra ?

A5: Yes, we could offer the sample for free charge but freight cost by yourself.

Q6: What is your terms of payment ?

A6: Payment below 1000USD, 100% in advance. Payment up to 1000USD, 50% T/T in advance, balance before shipment.

¡Su mensaje debe tener entre 20 y 3.000 caracteres!

¡Su mensaje debe tener entre 20 y 3.000 caracteres! ¡Por favor revise su correo electrónico!

¡Por favor revise su correo electrónico!  ¡Su mensaje debe tener entre 20 y 3.000 caracteres!

¡Su mensaje debe tener entre 20 y 3.000 caracteres! ¡Por favor revise su correo electrónico!

¡Por favor revise su correo electrónico!